Sunday, October 10, 2010

Saturday, October 9, 2010

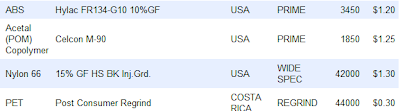

Price Updates in USA and Costa Rica.

Thursday, October 7, 2010

Polymer Price Report in Pakistan.

Tuesday, October 5, 2010

The intricacies of the Plastic Injection Moulding Process

Plastic is a very widely used material that has acquired popularity owing to its diverse usability and durability. It is possible to mould plastic to any form and produce products that cater to a wide category of consumer demand. This has led to the formation of a plastic based industry that serves the demands of its client on the basis of mass production. One of the most used methods of mass production of plastic is the Plastic Injection Moulding system. A comparatively old method, this has been in use since the 1800s and has acquired a certain credibility among manufacturers.

Plastic injection Moulding is a very simple process and can be used in the production of material that range from small bottle caps to entire body equipment of cars. Although the process is simple, its machinery is fairly complex and requires a certain degree of specialization for its manufacturing and handling. The Plastic Injection Moulding process was invented by John Wesley Hyatt in 1868, by using a plunger method. The technology for this process has now evolved.

Most manufacturing units make use of heated barrels where the liquefied plastic is fed. It is mixed with plastic granules and forced to form a mold cavity. Once this happens, the molded cavity is cooled and then hardened. The clamping part of the machine then goes on to mould the plastic into desirable shape. The engineer can then design the mould and then the mold is manufactured by the company in iron or aluminium to make suitable parts in precision machines.

Plastic Injection Moulding is used in the production of almost all the household appliances that are used today. This is the most preferred method in manufacturing such idle parts in large volumes. The low cost of labour, ability to use material in various ways, minimal scrap losses are the advantages gained by the use of Plastic Injection Moulding. There is also the development of high tolerance during the manufacturing process. The thickness of the mould is one important aspect that needs to be taken into consideration. Normally a mould with a set thickness is preferred.This prevents any change in the mechanical properties of the plastic.

The material used for moulding has to be assessed for its strength and function and the different parameters required are to be taken into account before going into production. Materials mainly used in the Plastic Injection Moulding process are thermoplastics or thermosetting plastics. Both are types of polymers. Nylon, polyethylene and polystyrene are some of the widely used thermoplastics while vulcanized rubber and bakelite are more used as thermosetting plastics.

Injection moulders use materials from a varied source to produce a varied amount of products. In the 1990s there were about 18000 materials used in production, and it has kept on increasing at the rate of 750 materials every year. The materials are chosen by the product designers in accordance with the products they intend to produce.

Plastic injection Moulding is a very simple process and can be used in the production of material that range from small bottle caps to entire body equipment of cars. Although the process is simple, its machinery is fairly complex and requires a certain degree of specialization for its manufacturing and handling. The Plastic Injection Moulding process was invented by John Wesley Hyatt in 1868, by using a plunger method. The technology for this process has now evolved.

Most manufacturing units make use of heated barrels where the liquefied plastic is fed. It is mixed with plastic granules and forced to form a mold cavity. Once this happens, the molded cavity is cooled and then hardened. The clamping part of the machine then goes on to mould the plastic into desirable shape. The engineer can then design the mould and then the mold is manufactured by the company in iron or aluminium to make suitable parts in precision machines.

Plastic Injection Moulding is used in the production of almost all the household appliances that are used today. This is the most preferred method in manufacturing such idle parts in large volumes. The low cost of labour, ability to use material in various ways, minimal scrap losses are the advantages gained by the use of Plastic Injection Moulding. There is also the development of high tolerance during the manufacturing process. The thickness of the mould is one important aspect that needs to be taken into consideration. Normally a mould with a set thickness is preferred.This prevents any change in the mechanical properties of the plastic.

The material used for moulding has to be assessed for its strength and function and the different parameters required are to be taken into account before going into production. Materials mainly used in the Plastic Injection Moulding process are thermoplastics or thermosetting plastics. Both are types of polymers. Nylon, polyethylene and polystyrene are some of the widely used thermoplastics while vulcanized rubber and bakelite are more used as thermosetting plastics.

Injection moulders use materials from a varied source to produce a varied amount of products. In the 1990s there were about 18000 materials used in production, and it has kept on increasing at the rate of 750 materials every year. The materials are chosen by the product designers in accordance with the products they intend to produce.

Monday, October 4, 2010

Glass-reinforced plastic (GRP) And Its Usages

By: Jason Paget

Glass-reinforced plastic (GRP), is a composite material or fibre reinforced plastic made of a plastic reinforced by fine fibers made of glass. Like graphite-reinforced plastic, the composite material is commonly referred to by the name of its reinforcing fibers (fiberglass), an example of part-for-whole metonymy.

First usages of GRP

GRP was originally developed in the UK during the Second World War as a replacement for the molded plywood used in aircraft radomes, its first main civilian application was for building of boats, where it gained acceptance in the 1950s, and now plays a dominant role. GRP is a versatile material with many uses.

Telecommunications industry

GRP is used in the telecommunications industry for shrouding the visual appearance of antennas, due to its RF permeability and low signal attenuation properties. It may also be used to shroud the visual appearance of other equipment where no signal permeability is required, such as equipment cabinets and steel support structures, due to the ease with which it can be molded, manufactured and painted to custom designs, to blend in with existing structures or brickwork.

Storage Tanks

Storage tanks can be made of GRP with capacities up to about 300 tonnes. The smaller tanks can be made with chopped strand mat cast over a thermoplastic inner tank which acts as a preform during construction. Much more reliable tanks are made using woven mat or filament wound fibre with the fibre orientation at right angles to the hoop stress imposed in the side wall by the contents. They tend to be used for chemical storage because the plastic liner (often polypropylene) is resistant to a wide range of strong chemicals. GRP tanks are also used for septic tanks.

House building

GRP also used in the house building market for the production of roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping systems, heads with keystones and sills. The use of GRP for these applications provides for a much faster installation and due to the reduced weight manual handling issues are reduced. With the advent of high volume manufacturing processes it is possible to construct GRP brick effect panels which can be used in the construction of composite housing. These panels can be constructed with the appropriate insulation which reduces heat loss.

For Piping

GRP and GRE pipe systems can be used for a variety of applications, above and under the ground.

Chopped Strand Mat

Chopped strand mat or CSM is a form of reinforcement used in GRP. It consists of glass-fibres laid randomly across each other and held together by a binder. It is typically processed using the hand lay-up technique, where sheets of material are placed in a mold and brushed with resin. Because the binder dissolves in resin, the material easily conforms to different shapes when wetted out. After the resin cures, the hardened product can be taken from the mold and finished. Using chopped strand mat gives a GRP with isotropic in-plane material properties.

GRP is an immensely versatile material which combines lightweight with inherent strength to provide a weather resistant finish, with a variety of surface texture and an unlimited colour range available.

Glass-reinforced plastic (GRP), is a composite material or fibre reinforced plastic made of a plastic reinforced by fine fibers made of glass. Like graphite-reinforced plastic, the composite material is commonly referred to by the name of its reinforcing fibers (fiberglass), an example of part-for-whole metonymy.

First usages of GRP

GRP was originally developed in the UK during the Second World War as a replacement for the molded plywood used in aircraft radomes, its first main civilian application was for building of boats, where it gained acceptance in the 1950s, and now plays a dominant role. GRP is a versatile material with many uses.

Telecommunications industry

GRP is used in the telecommunications industry for shrouding the visual appearance of antennas, due to its RF permeability and low signal attenuation properties. It may also be used to shroud the visual appearance of other equipment where no signal permeability is required, such as equipment cabinets and steel support structures, due to the ease with which it can be molded, manufactured and painted to custom designs, to blend in with existing structures or brickwork.

Storage Tanks

Storage tanks can be made of GRP with capacities up to about 300 tonnes. The smaller tanks can be made with chopped strand mat cast over a thermoplastic inner tank which acts as a preform during construction. Much more reliable tanks are made using woven mat or filament wound fibre with the fibre orientation at right angles to the hoop stress imposed in the side wall by the contents. They tend to be used for chemical storage because the plastic liner (often polypropylene) is resistant to a wide range of strong chemicals. GRP tanks are also used for septic tanks.

House building

GRP also used in the house building market for the production of roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping systems, heads with keystones and sills. The use of GRP for these applications provides for a much faster installation and due to the reduced weight manual handling issues are reduced. With the advent of high volume manufacturing processes it is possible to construct GRP brick effect panels which can be used in the construction of composite housing. These panels can be constructed with the appropriate insulation which reduces heat loss.

For Piping

GRP and GRE pipe systems can be used for a variety of applications, above and under the ground.

- Firewater systems

- Cooling water systems

- Drinking water systems

- Waste water systems/Sewage systems

- Gas systems

Chopped Strand Mat

Chopped strand mat or CSM is a form of reinforcement used in GRP. It consists of glass-fibres laid randomly across each other and held together by a binder. It is typically processed using the hand lay-up technique, where sheets of material are placed in a mold and brushed with resin. Because the binder dissolves in resin, the material easily conforms to different shapes when wetted out. After the resin cures, the hardened product can be taken from the mold and finished. Using chopped strand mat gives a GRP with isotropic in-plane material properties.

GRP is an immensely versatile material which combines lightweight with inherent strength to provide a weather resistant finish, with a variety of surface texture and an unlimited colour range available.

How to Wash Polyester Bow Ties

Polyester bow ties are made from polymers that contain natural chemicals. Polyester is popular because it is durable. During the 1970s, polyester bow tie is very common among the public. Now, it is making a slight comeback. Polyester bow tie holds its shape. It won?t become crease when you crumple or fold it.

Polyester bow ties are made from polymers that contain natural chemicals. Polyester is popular because it is durable. During the 1970s, polyester bow tie is very common among the public. Now, it is making a slight comeback. Polyester bow tie holds its shape. It won?t become crease when you crumple or fold it. It is quite easy to care for. Just like other things, you must wash it from time to time so that it can last for a long time.

You can wash polyester bow ties with your hands or washing machine. It is recommended that you hand wash the polyester bow tie because the rotator in the washing machine can damage it.

Polyester bow tie is not resistant against stain. If you accidentally make it dirty, it can be difficult to remove the stain. For machine wash, you should adjust the setting to press cycler. The water that is used to wash the polyester bow tie must be warm. Machine washed polyester bow ties tend to become stiff. To solve this problem, you can pour it a few drops of fabric softener in the washing machine. The fabric softener will make the polyester bow ties have a softer feel. It will also reduce the static electricity so that it won?t cause shock to you when wearing it.

After polyester bow tie is washed, you must put it into the dryer with low heat setting. Later, you can hang it on an airy place that has a warm temperature. You should not hang it on the clothes rack because it will cause stain on it. Most polyester bow tie can be cleaned. When ironing, make sure you set it to the temperature for the polyester fabric. If the temperature is set too high, it can scorch and melt the polyester fabric. Once the polyester bow tie is dried, you must quickly bring it into the home. If you over dry the polyester bow tie, it can shrink over time.

Polyester bow ties become yellow after a period of time. You can prevent this by using a dishwashing detergent mixture. The dishwashing detergent mixture consists of ? cup of dishwashing detergent and 1 gallon of water. The polyester bow tie should be soaked in the dishwashing detergent mixture for some time. After that, you can wash the bow tie. During rinsing, you can add ? cup of white vinegar to the water.

If you want to hand wash the bow tie, make sure you use a mild detergent.

Strong detergent will cause discoloration in the bow tie. If there are some stains on the bow tie, be sure to clean them away quickly. If you linger, the stain will be difficult to clean away. To remove the stain, you can damp a cloth in tepid water and rub against it up and down. After that, you should take a dry cloth that is soaked in clean water and gently rub on the stained area. If the stain is not removed, you can hand it to the dry cleaner service.

Polyester bow ties are made from polymers that contain natural chemicals. Polyester is popular because it is durable. During the 1970s, polyester bow tie is very common among the public. Now, it is making a slight comeback. Polyester bow tie holds its shape. It won?t become crease when you crumple or fold it. It is quite easy to care for. Just like other things, you must wash it from time to time so that it can last for a long time.

You can wash polyester bow ties with your hands or washing machine. It is recommended that you hand wash the polyester bow tie because the rotator in the washing machine can damage it.

Polyester bow tie is not resistant against stain. If you accidentally make it dirty, it can be difficult to remove the stain. For machine wash, you should adjust the setting to press cycler. The water that is used to wash the polyester bow tie must be warm. Machine washed polyester bow ties tend to become stiff. To solve this problem, you can pour it a few drops of fabric softener in the washing machine. The fabric softener will make the polyester bow ties have a softer feel. It will also reduce the static electricity so that it won?t cause shock to you when wearing it.

After polyester bow tie is washed, you must put it into the dryer with low heat setting. Later, you can hang it on an airy place that has a warm temperature. You should not hang it on the clothes rack because it will cause stain on it. Most polyester bow tie can be cleaned. When ironing, make sure you set it to the temperature for the polyester fabric. If the temperature is set too high, it can scorch and melt the polyester fabric. Once the polyester bow tie is dried, you must quickly bring it into the home. If you over dry the polyester bow tie, it can shrink over time.

Polyester bow ties become yellow after a period of time. You can prevent this by using a dishwashing detergent mixture. The dishwashing detergent mixture consists of ? cup of dishwashing detergent and 1 gallon of water. The polyester bow tie should be soaked in the dishwashing detergent mixture for some time. After that, you can wash the bow tie. During rinsing, you can add ? cup of white vinegar to the water.

If you want to hand wash the bow tie, make sure you use a mild detergent.

Strong detergent will cause discoloration in the bow tie. If there are some stains on the bow tie, be sure to clean them away quickly. If you linger, the stain will be difficult to clean away. To remove the stain, you can damp a cloth in tepid water and rub against it up and down. After that, you should take a dry cloth that is soaked in clean water and gently rub on the stained area. If the stain is not removed, you can hand it to the dry cleaner service.

BASF Increases Prices for Polyurethane Products in Europe

With immediate effect, or as contract terms allow, BASF will be increasing its prices for MDI and polyols and polyurethane systems in Europe on average by 200 Euro per metric ton.

About BASF Polyurethanes

BASF is the leading supplier of Polyurethane Solutions for systems, specialties and PU basic products. With its global network of 38 polyurethane system houses and its comprehensive product and service portfolio, BASF is the preferred partner of its customers in many industries. The BASF brand “PU Solutions Elastogran” represents over 40 years of experience of the market and technology leadership for Polyurethane systems and specialty elastomers in Europe.

In the extremely service-oriented business of polyurethane systems and specialties, reliable PU experience and competence are crucial. Through its system house network, BASF provides fast local support, from technical service and sales to production and marketing during the development of customized solutions. With its world-scale plants, BASF secures its leading market position in the production of polyurethane basic products in all regions of the world.

Polyurethanes make life more comfortable, safer and more pleasant while helping to save energy sustainably. They contribute towards improved insulation of buildings and more attractive, lightweight design of cars. Producers of shoes, mattresses and household goods as well as sports equipment use the unique advantages of polyurethanes provided with the knowledge and expertise of the polyurethane experts of BASF world-wide.

About BASF Polyurethanes

BASF is the leading supplier of Polyurethane Solutions for systems, specialties and PU basic products. With its global network of 38 polyurethane system houses and its comprehensive product and service portfolio, BASF is the preferred partner of its customers in many industries. The BASF brand “PU Solutions Elastogran” represents over 40 years of experience of the market and technology leadership for Polyurethane systems and specialty elastomers in Europe.

In the extremely service-oriented business of polyurethane systems and specialties, reliable PU experience and competence are crucial. Through its system house network, BASF provides fast local support, from technical service and sales to production and marketing during the development of customized solutions. With its world-scale plants, BASF secures its leading market position in the production of polyurethane basic products in all regions of the world.

Polyurethanes make life more comfortable, safer and more pleasant while helping to save energy sustainably. They contribute towards improved insulation of buildings and more attractive, lightweight design of cars. Producers of shoes, mattresses and household goods as well as sports equipment use the unique advantages of polyurethanes provided with the knowledge and expertise of the polyurethane experts of BASF world-wide.

Sunday, October 3, 2010

Acrylic Plastic Sheets – An Invention With Hundreds of Uses

Acrylic plastic sheets can be referred to as the next best thing to glass, with many of its own unique additions. It’s a very beneficial and commodious clear plastic, and is the closest material to glass with 93% of clarity, along with many other properties which make it far more superior.

It comes from a family of synthetic plastic substances and is derived from acrylic acid. Acrylic plastic has been segregated in four brands namely Plexiglas, Lucite, Perspex, and Crystallite; the brands are all versions of polymethyl methacrylate (PMMA).

All are superior quality plastics which are tough, shatter proof and resistant to ultraviolet radiations and weathering and most importantly are highly transparent. Thick sheets of glass have a greenish tint but acrylic plastic sheets retain their transparency even at very high density.

Acrylic plastic has become the mainstay of a large number of industries and is being used for making windshields, shower doors, skylights, windows, automobile taillights, aquariums, outdoor signs and a lot more. Its basic advantages include its strength, acrylic plastic is many times lighter than glass, yet its far stronger and impact resistant, also one of its most unique qualities is the flexibility and the ease with which it can be molded into multitude shapes. The fact that it can be easily scratched is considered its downside; however the scratches can be easily buffed out, making it clear as it was on the very first day of installation.

Acrylic plastic sheets can be bought from plastic stores, directly from the markets and from the online stores as well. The sheets are available in pre-defined sizes starting from 24″ x48″ to 72″x186″, and thickness varying from 1/16″ to 4″. Many showrooms also provide complete cutting and shaping services, with precision ‘cut to size’ capabilities facilitated by the professional service experts.

These days there is a colossal variety of acrylic plastic available including cast, extruded, clear, colored, tinted, laser cut and also mirrored. Apart from the sheet you can also obtain this resourceful plastic in the form of tubes, cubes, rods and balls. It’s often said that acrylic plastic sheets turn brittle and yellow over a period of time and also develops cracks. However this happens only to the normal plastics, Acrylic plastics retain their shapes and colors over a long period of time.

Cleaning and maintenance of this plastic is also fairly easy as it doesn’t need any special sprays, some mild soap or good quality detergent along with lukewarm water suffices, for drying a dry cloth or chamois is apt.

If you are looking forward to remodeling your bathroom or aquarium or even plan to add a new look to your windows, acrylic could be a very intelligent choice. Though it’s more expensive than glass, but the advantages far outweigh the price. It’s the material of the present and the future, and is being used more than it ever was in the past, even though its advent into the commercial markets dates back to 1936. Other important places where it’s famously used include malls, colleges, institutions, hospitals and commercial offices. About 32mm of superior quality acrylic plastic sheet is bullet resistant and is a favorite for use in the presidential motorcades and for protection and security for dignitaries around the world.

It comes from a family of synthetic plastic substances and is derived from acrylic acid. Acrylic plastic has been segregated in four brands namely Plexiglas, Lucite, Perspex, and Crystallite; the brands are all versions of polymethyl methacrylate (PMMA).

All are superior quality plastics which are tough, shatter proof and resistant to ultraviolet radiations and weathering and most importantly are highly transparent. Thick sheets of glass have a greenish tint but acrylic plastic sheets retain their transparency even at very high density.

Acrylic plastic has become the mainstay of a large number of industries and is being used for making windshields, shower doors, skylights, windows, automobile taillights, aquariums, outdoor signs and a lot more. Its basic advantages include its strength, acrylic plastic is many times lighter than glass, yet its far stronger and impact resistant, also one of its most unique qualities is the flexibility and the ease with which it can be molded into multitude shapes. The fact that it can be easily scratched is considered its downside; however the scratches can be easily buffed out, making it clear as it was on the very first day of installation.

Acrylic plastic sheets can be bought from plastic stores, directly from the markets and from the online stores as well. The sheets are available in pre-defined sizes starting from 24″ x48″ to 72″x186″, and thickness varying from 1/16″ to 4″. Many showrooms also provide complete cutting and shaping services, with precision ‘cut to size’ capabilities facilitated by the professional service experts.

These days there is a colossal variety of acrylic plastic available including cast, extruded, clear, colored, tinted, laser cut and also mirrored. Apart from the sheet you can also obtain this resourceful plastic in the form of tubes, cubes, rods and balls. It’s often said that acrylic plastic sheets turn brittle and yellow over a period of time and also develops cracks. However this happens only to the normal plastics, Acrylic plastics retain their shapes and colors over a long period of time.

Cleaning and maintenance of this plastic is also fairly easy as it doesn’t need any special sprays, some mild soap or good quality detergent along with lukewarm water suffices, for drying a dry cloth or chamois is apt.

If you are looking forward to remodeling your bathroom or aquarium or even plan to add a new look to your windows, acrylic could be a very intelligent choice. Though it’s more expensive than glass, but the advantages far outweigh the price. It’s the material of the present and the future, and is being used more than it ever was in the past, even though its advent into the commercial markets dates back to 1936. Other important places where it’s famously used include malls, colleges, institutions, hospitals and commercial offices. About 32mm of superior quality acrylic plastic sheet is bullet resistant and is a favorite for use in the presidential motorcades and for protection and security for dignitaries around the world.

Friday, October 1, 2010

EU imposes new duties on Iran, Pakistan, UAE plastics

BRUSSELS, Sept 29 (Reuters) - The European Union imposed new duties on plastics from Iran, Pakistan and the United Arab Emirates on Wednesday, saying the three were illegally subsidising exports to Europe's growing soft-drinks market.

The decision means Polyethylene terephthalate from Iran, Pakistan and the UAE -- used for bottles and food packaging -- will face EU import duties of 139.70 euros ($188.1), 44.02 euros and 42.34 euros per tonne respectively until 2015.

"In view of the magnitude of the countervailable subsidies found and in the light of the level of the injury caused to the (European) Union's industry, it is considered necessary" to launch the new tariffs, the EU's executive Commission said in the EU's official journal.

The duties are valid for up to five years and reflect Europe's concern that EU industry is falling behind oil-rich states with competitive and booming plastics markets.

European citizens bought about 100 billion plastic bottles last year -- one in five bottles sold worldwide -- creating a 3 billion euro ($3.9 billion) market for the plastic.

Europe's decision prompted a senior UAE trade official to warn of disruptions to trade.

"There are many countries that have started to impose certain tariffs to protect their national industry, especially after the (economic) crisis. But this doesn't serve the interest of trade, we can't do trade like this," Juma al-Kait, executive director for foreign trade affairs, told Reuters.

Such a decision would adversely affect the UAE's economy because most of its non-crude oil exports are petrochemical raw materials and feedstocks, including plastics, he said.

Plastic bottle makers including Danone (DANO.PA) and Coca-Cola Group (KO.N) have also warned against the duties.

The decision means Polyethylene terephthalate from Iran, Pakistan and the UAE -- used for bottles and food packaging -- will face EU import duties of 139.70 euros ($188.1), 44.02 euros and 42.34 euros per tonne respectively until 2015.

"In view of the magnitude of the countervailable subsidies found and in the light of the level of the injury caused to the (European) Union's industry, it is considered necessary" to launch the new tariffs, the EU's executive Commission said in the EU's official journal.

The duties are valid for up to five years and reflect Europe's concern that EU industry is falling behind oil-rich states with competitive and booming plastics markets.

European citizens bought about 100 billion plastic bottles last year -- one in five bottles sold worldwide -- creating a 3 billion euro ($3.9 billion) market for the plastic.

Europe's decision prompted a senior UAE trade official to warn of disruptions to trade.

"There are many countries that have started to impose certain tariffs to protect their national industry, especially after the (economic) crisis. But this doesn't serve the interest of trade, we can't do trade like this," Juma al-Kait, executive director for foreign trade affairs, told Reuters.

Such a decision would adversely affect the UAE's economy because most of its non-crude oil exports are petrochemical raw materials and feedstocks, including plastics, he said.

Plastic bottle makers including Danone (DANO.PA) and Coca-Cola Group (KO.N) have also warned against the duties.

Subscribe to:

Comments (Atom)